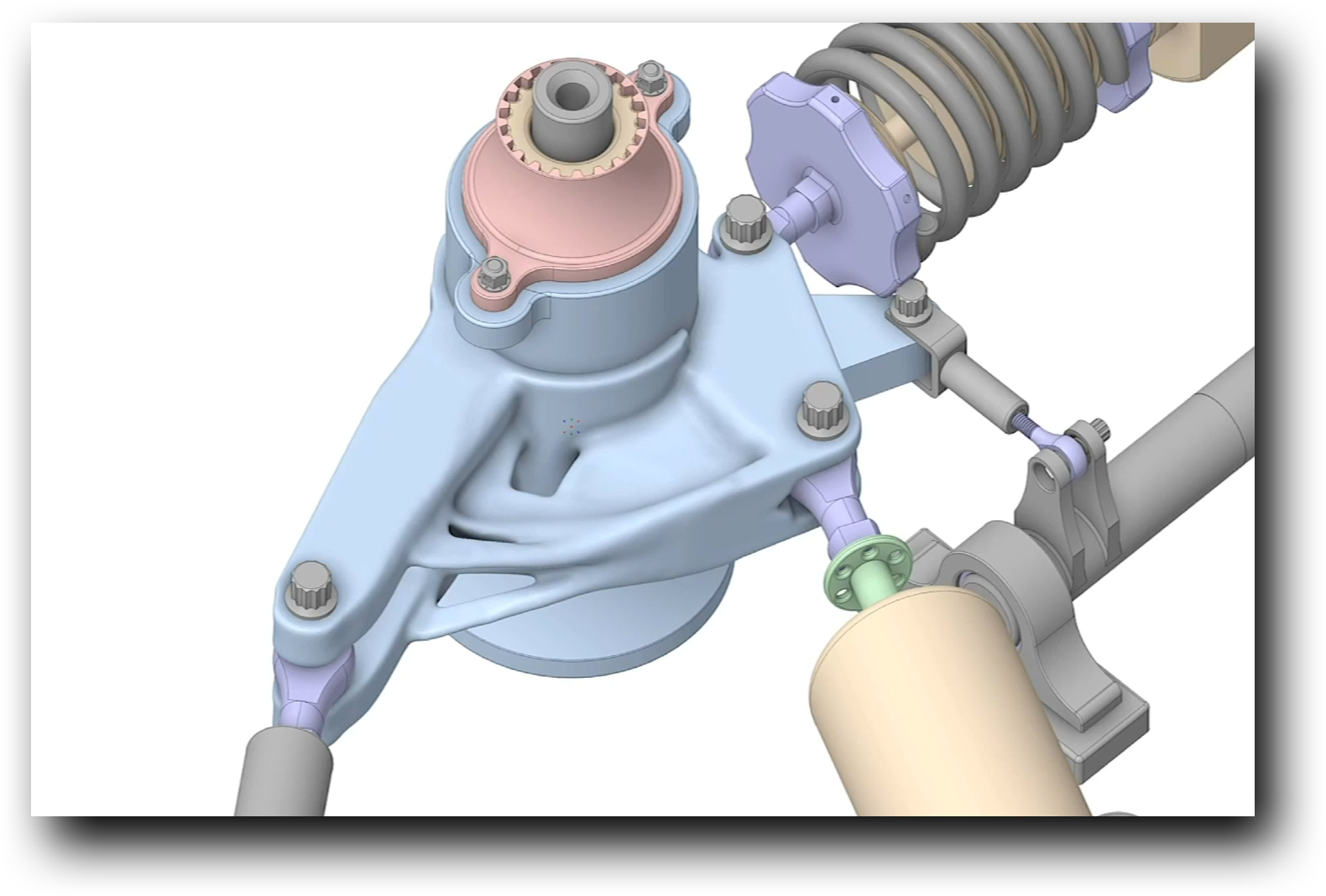

Design freedom

AM gives you the freedom to create shapes with complex geometries with multiple moving parts all in a single print process. With AM inhouse or produced by Service Providers, your designers can finally create the parts and products you need – not only parts you can produce.

But AM design and production goes further. It is not only about the product itself, with AM a designer can create

– new jigs and fixtures, to simplify production and installation task for the employees

– better, light-weight robotic end-of-arm tools to accelerate the production

– new grippers to avoid shipping damage during distribution

– new molds or cavities with integrated sensors and cooling channels

– new airflow tubes for better performance

And those a just a few examples – only the creativity of the designer limits the possibilities.

However, even though AM allows you to produce basically any geometry, only knowing the principals and challenges of AM can help reduce printing time and cost.

Our team can help your designers, engineers and the other employees to understand the possibilities and the value of AM by a combination of education and cross department workshops.

But AM design and production goes further. It is not only about the product itself, with AM a designer can create

– new jigs and fixtures, to simplify production and installation task for the employees

– better, light-weight robotic end-of-arm tools to accelerate the production

– new grippers to avoid shipping damage during distribution

– new molds or cavities with integrated sensors and cooling channels

– new airflow tubes for better performance

And those a just a few examples – only the creativity of the designer limits the possibilities.

However, even though AM allows you to produce basically any geometry, only knowing the principals and challenges of AM can help reduce printing time and cost.

Our team can help your designers, engineers and the other employees to understand the possibilities and the value of AM by a combination of education and cross department workshops.

Design for Additive Manufacturing (DfAM)

When essential AM ideas and concepts are ingrained into designers mind, it is possible to gain the maximum value of AM.

Design for AM is not only about redesigning a part so it prints properly, DfAM is the prerequisite to unleash the real advantage of Additive Design – to reduce print failures, optimize print cost and maximize production efficiency.

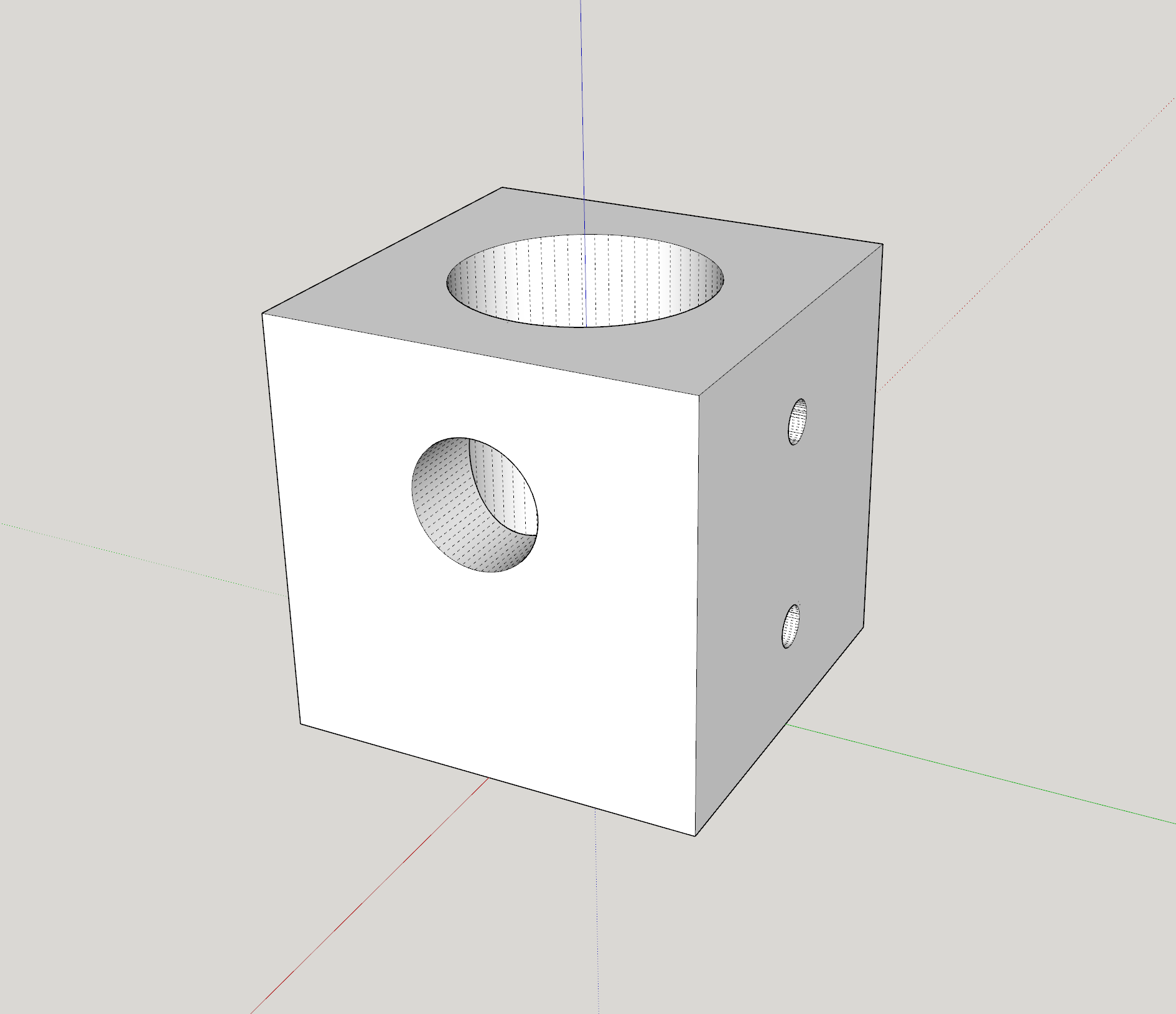

Example:

Originally designed for CNC

Dimension: 100x100x100mm Print time: 7d 22h Mass of printed part: 2.48 kgBasic design optimization for AM

Dimension: 80x81x100mm Print time 1d 13h Mass of printed part: 0,419kgTopology optimization

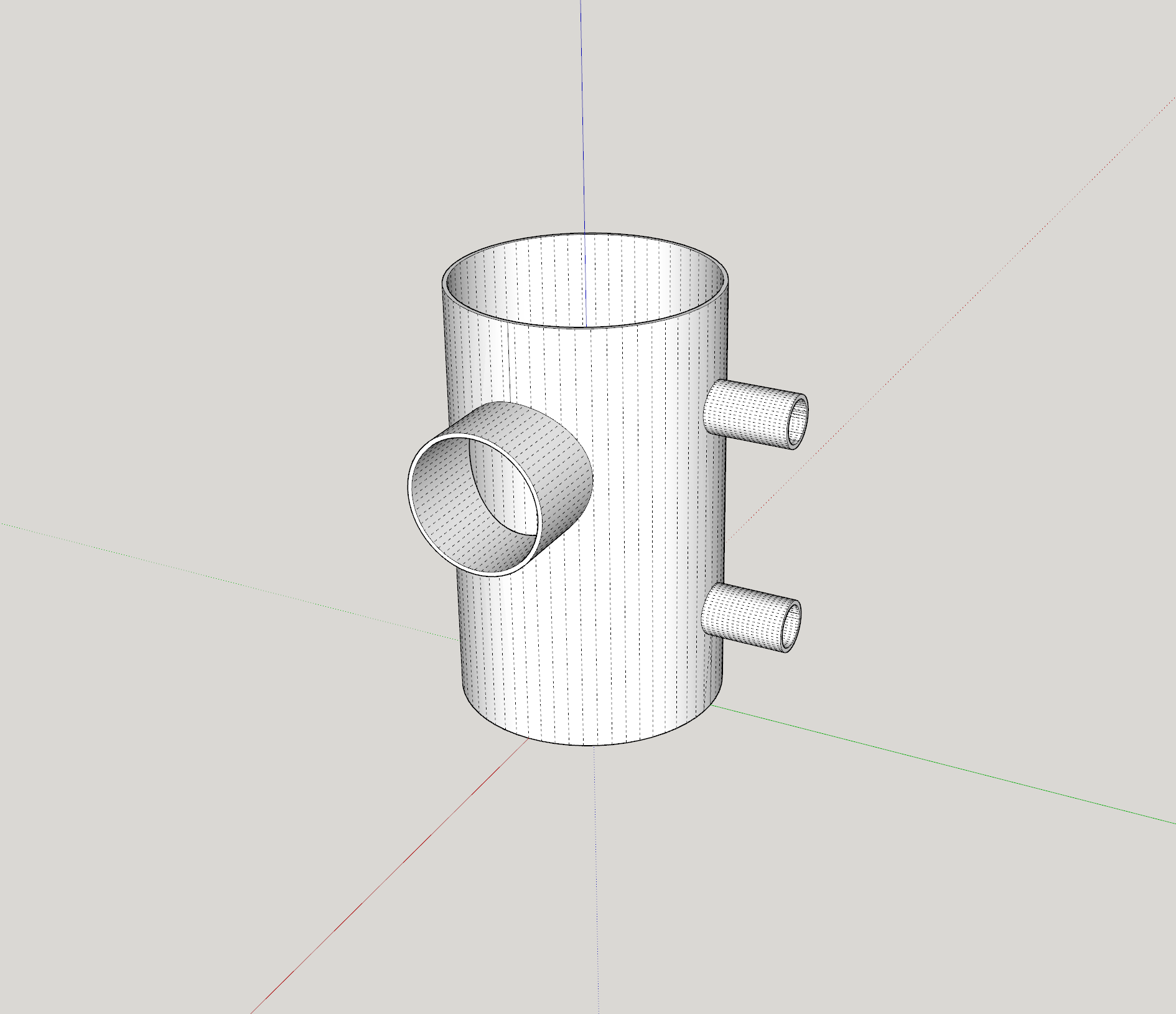

Topology optimization is another key element to gain the maximum value of Additive manufacturing.

Topology optimization for AM is unique, inasmuch it exploits what is effectively impossible to achieve using conventional manufacturing methods, giving the designer opportunities to challenge and create topology enabling enhancement in part performance.